If your generator stops producing voltage, check the following:

- Ensure there is enough fuel and a clean air filter.

- Inspect the spark plug for issues.

- Verify that no circuit breakers have tripped.

It’s also vital to examine the voltage regulator’s condition, as it’s essential for proper generator function.

Don’t forget to assess the generator head, stator, and rotor, as these components are critical for voltage generation.

Addressing these areas should help restore your generator’s voltage output efficiently.

Fuel Level

Check your generator’s fuel tank to make sure it has enough fuel. Low fuel can stop it from making power.

Check the fuel gauge often and fill the tank when needed to keep the generator ready. Not having enough fuel is a common reason for a generator not working right.

When looking at fuel, how much you have isn’t the only thing that matters—the fuel must be good quality. Bad or dirty fuel can make the engine run poorly or get damaged, which then affects power output.

Use the right fuel as the maker says and make sure it’s fresh. Old fuel might make it hard to start or not burn well.

Keep the generator’s fuel level right to make sure you have power when you need it. This helps you stay ready for power cuts. Your generator is important for keeping things going, and being ready shows you’re prepared.

Air Filter

Keeping enough fuel for your generator is important, just like having a clean air filter for good combustion and power. A dirty air filter blocks airflow, which is important for efficient combustion in your generator’s engine. Check the air filter often for dirt or debris that might stop it from working well.

Look closely at the air filter. If it’s blocked, you need to fix it. A blocked air filter can cause poor air intake, creating an imbalanced air-fuel mix. This can make the engine run lean, with too much air and not enough fuel. That can make your generator produce less voltage.

Clean or change the air filter as needed to make sure it’s not causing voltage issues. Taking care of your generator this way shows responsibility and makes sure it works when you need it.

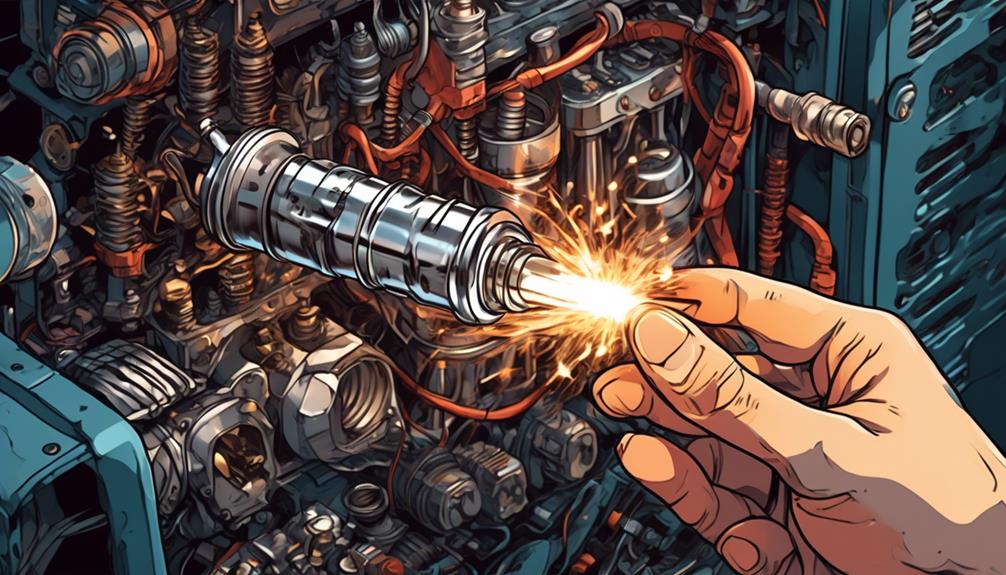

Spark Plug

Check your generator’s spark plug regularly. A bad spark plug can cause poor ignition and low voltage. Look for carbon or oil on the plug, which means it’s dirty. A worn electrode also means a weak spark and poor generator performance.

Make sure the spark plug gap is right. If it’s wrong, the generator mightn’t run well. Use a gap gauge to measure it and match it with the maker’s suggested gap.

Keep the spark plug clean and gapped correctly to keep your generator running smoothly.

Oil Level

Check Oil Level: Always check the oil before starting your generator. Use the dipstick. Make sure oil touches between the high and low marks.

Know the Shutdown Feature: Generators stop if oil is too low. This saves the engine from damage.

Maintain Regularly: Follow the manufacturer’s schedule for oil checks and changes. Old or dirty oil can lower performance and stop electricity production.

Keep your generator’s oil level right to avoid power loss. Use these tips to keep your lights on.

Circuit Breaker

Start generator maintenance by checking the circuit breaker for a reset if it has tripped. This is a common issue that stops power because the breaker cuts off electricity when there’s too much for safety. Find the breaker, usually in a small panel on the generator. If it’s off or not fully on, it likely tripped.

Make sure the cause of the trip is fixed before resetting to avoid the same problem. Check all equipment for faults and make sure the generator isn’t too loaded with electricity demand.

To reset, push the breaker fully off, then on. This should make the electricity flow again. If it trips right away, you need to look more into the generator or what’s connected to it. If the breaker keeps tripping, get a professional to check it.

Voltage Regulator

Check your circuit breaker first and make sure it works right. Next, look at your generator’s voltage regulator. This part keeps the output voltage steady. If it’s broken, your generator mightn’t make enough voltage or any at all. This could be why your generator isn’t working well.

Here’s how to check the voltage regulator:

- Visual Inspection: Look for damage like burn marks or rust on the voltage regulator. These signs can mean it’s not working well.

- Electrical Testing: Test the voltage regulator with a multimeter. If the reading is way off from what it should be, the regulator might be broken.

- Replacement Evaluation: If you find damage or the voltage is wrong, you might need a new voltage regulator. Get one that fits your generator to avoid more problems.

Generator Head Issues

Check the generator head for damage or faults to fix voltage problems. The generator head or alternator turns mechanical energy into electrical energy. Problems here mean no voltage.

Concerns and Emotions:

- Physical Damage: Anxiety, Urgency

- Burnt Components: Frustration

- Wiring Issues: Confusion

- Bearing Failures: Disappointment

Inspect the generator head for cracks or burns. These issues need quick action. Look at the wiring for corrosion or loose connections, which can be hidden and confusing. Listen for odd sounds that could mean bearing issues, which might need more repair work.

Fixing generator head problems quickly keeps your power supply steady and supports your community.

Automatic Voltage Regulator (AVR)

An Automatic Voltage Regulator (AVR) is key for keeping your generator’s voltage steady. Check it if your generator has voltage issues.

Here’s what to do:

- Visual Inspection: Look at the AVR for damage like burnt parts or rust. Damage means the AVR might need to be replaced.

- Electrical Testing: Use a multimeter to check the AVR’s voltage. If the reading is off or there’s no voltage, the AVR mightn’t be working right.

- Connections and Wiring: Make sure all wires to the AVR are tight and clean. Bad wiring can cause voltage problems or no power at all.

Stator and Rotor

Check your AVR is working right but you still have voltage problems, look at the stator and rotor. These parts make electricity. The stator is steel and copper that doesn’t move. The rotor is a magnet that spins to make a magnetic field. They work together to turn mechanical energy into electric energy.

Damaged or worn stator windings can mess up the magnetic flow and cause voltage trouble. A weak or uneven magnetic field from the rotor means it can’t make the right current in the stator. Your community values machines that work well and are reliable, so checking these parts well is a must.

Here’s a short guide for what to check:

| Stator Checks | Rotor Checks |

|---|---|

| Test Insulation Resistance | Check Magnetic Field Strength |

| Test for Continuous Windings | Check for Physical Damage |

| Look for Shorts | Inspect Bearings |

| Ensure It’s Clean and Dry | Check Balance and Alignment |

| Check for Overheat Signs | Inspect Slip Rings/Electrodes |